| 出版社 | IMARC Group |

| 出版年月 | 2024年9月 |

Smart Factory Market Size, Share, Trends and Forecast by Field Devices, Technology, End Use Industry, and Region, 2025-2033

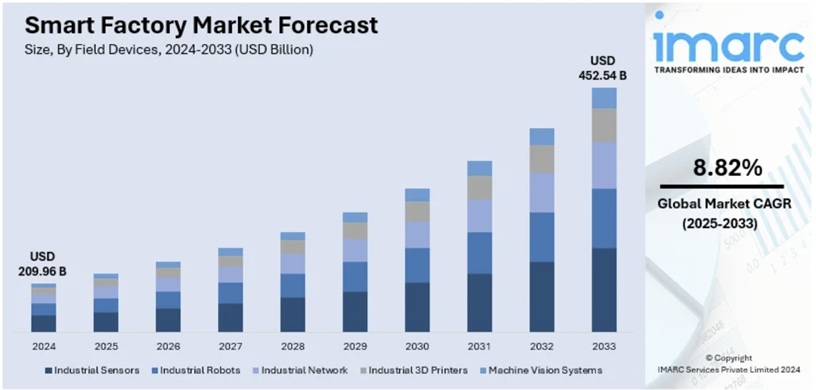

世界のスマートファクトリー市場規模は、2024年に2,099億6,000万米ドルと評価されました。IMARCグループは、今後、市場規模は2033年までに4,525億4,000万米ドルに達し、2025年から2033年にかけて8.82%の年平均成長率(CAGR)で成長すると予測しています。現在、アジア太平洋地域が市場を支配しており、2024年には45.5%以上の市場シェアを占める見込みです。産業オートメーションの需要増加、再生産業用ロボットや無線周波数識別(RFID)システムの導入増加、そしてクラウドコンピューティング、人工知能(AI)、モノのインターネット(IoT)との接続デバイスとの統合拡大などが、市場の成長を牽引する要因となっています。

製造業における業務効率化とコスト削減のニーズの高まりが、世界市場を牽引しています。同様に、リアルタイム監視、データ駆動型の意思決定、予知保全を可能にする産業用IoT(IIoT)技術の導入拡大も、市場を活性化させています。例えば、LGエレクトロニクスは2024年7月18日、66年にわたる製造業の専門知識にAIを統合することで、スマートファクトリー事業を加速させました。LGは生産技術研究所(PRI)を通じて、デジタルツイン技術、自律ロボット、生成AIなどのソリューションを提供し、2030年までに数兆ウォン規模の成長を目指す半導体や医薬品などの業界をターゲットにしています。さらに、持続可能でエネルギー効率の高い製造ソリューションとスケーラブルなロボット統合への需要が、市場拡大を牽引し続けています。

The global smart factory market size was valued at USD 209.96 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 452.54 Billion by 2033, exhibiting a CAGR of 8.82% from 2025-2033. Asia Pacific currently dominates the market, holding a market share of over 45.5% in 2024. The increasing demand for industrial automation, the rising adoption of refurbished industrial robots and radio frequency identification (RFID) systems, and the growing integration of connected devices with cloud computing, artificial intelligence (AI), and the Internet of Things (IoT) are some of the factors propelling the market.

Smart Factory Market Size, Share, Trends and Forecast

The global market is propelled by the rising need for operational efficiency and cost reduction in manufacturing. Similarly, the growing adoption of Industrial Internet of Things (IIoT) technologies enabling real-time monitoring, data-driven decision-making, and predictive maintenance, is providing an impetus to the market. For instance, on July 18, 2024, LG Electronics accelerated its smart factory business by integrating AI with 66 years of manufacturing expertise. Through its Production Engineering Research Institute (PRI), LG offers solutions such as Digital Twin technology, autonomous robots, and generative AI, targeting industries like semiconductors and pharmaceuticals with ambitious multi-trillion KRW growth goals by 2030. Additionally, the demand for sustainable, energy-efficient manufacturing solutions and scalable robotics integration continues to drive market expansion.

The United States is a key regional market and is growing due to the need for resilient supply chains and agile manufacturing to optimize production and respond to market shifts. An industry report highlights that 86% of U.S. manufacturers consider smart factories as key to competition by 2025, although only 16% currently have real-time visibility into operations. Smart factories enhance asset efficiency by 20%, improve product quality by 30%, and reduce costs by 30%. Furthermore, the steady adoption of real-time data analytics, cloud computing, and Industry 4.0 technologies is driving better decision-making and operational transparency. Government support for advanced manufacturing and the demand for customized products further propel growth in the market. Additionally, the growing focus on workforce safety, skill development, and cybersecurity integration ensures reliable operations and accelerates smart factory adoption across industries.

Smart Factory Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Field Devices Covered | Industrial Sensors, Industrial Robots, Industrial Network, Industrial 3D Printers, Machine Vision Systems |

| Technologies Covered | Product Lifecycle Management (PLM), Human Machine Interface (HMI), Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), Distributed Control Systems (DCS), Industrial Control System, Others |

| End Use Industries Covered | Pharmaceuticals, Food and Beverages, Chemical, Oil and Gas, Automotive and Transportation, Semiconductor and Electronics, Aerospace and Defense, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | ABB Ltd, Dassault Systèmes, Emerson Electric Co., General Electric Company, Honeywell International Inc., Johnson Controls International, Microsoft Corporation, Mitsubishi Electric Corporation, Robert Bosch GmbH, Schneider Electric SE, Siemens AG, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |